The Power of Hemp Fibers: Exploring Strength and Durability in Construction and Products

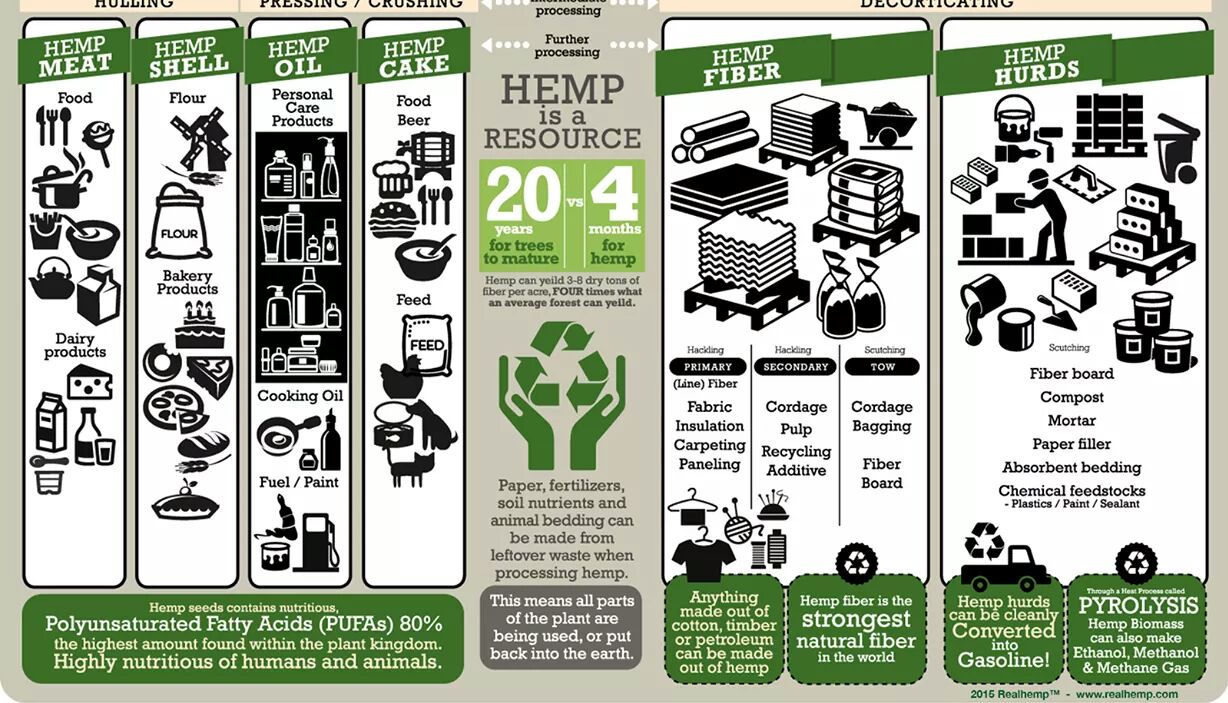

Hemp is a versatile plant that can be used for various purposes, including construction, textiles, and composites. Hemp fibers have gained attention in recent years due to their exceptional strength, durability, and sustainability, making them an attractive alternative to traditional building materials and products. This article explores the properties of hemp fibers, their applications in construction, textiles, and composites, their environmental impact, and the future prospects of this innovative material.

Properties of Hemp Fibers: Strength and Durability

Hemp fibers are known for their exceptional strength and durability, making them ideal for various applications. Hemp fibers have a tensile strength that is eight times higher than cotton fibers, making them more resilient to wear and tear. They also have a high elasticity modulus, which means they can withstand higher stress without breaking. Hemp fibers are resistant to mold, mildew, and pests, making them a low-maintenance material. Additionally, hemp fibers have a high absorbency rate, which allows them to hold moisture without weakening the material.

Hempcrete: A Sustainable Alternative to Traditional Building Materials

Hempcrete is a sustainable building material made from hemp fibers, lime, and water. Hempcrete is lightweight, strong, and durable, making it an attractive alternative to traditional building materials. Hempcrete is also a breathable material, which means it allows vapor to pass through, reducing the risk of moisture buildup and mold growth. Hempcrete is environmentally friendly since it is made from renewable resources and does not emit harmful chemicals or toxins.

Hemp Fiberboards: High Performance and Eco-Friendly

Hemp fiberboards are made from compressed hemp fibers and can be used for a variety of applications, including flooring, walls, and furniture. Hemp fiberboards are lightweight, durable, and resistant to moisture, making them a suitable material for high-traffic areas. Additionally, hemp fiberboards are eco-friendly since they are made from renewable resources and do not emit harmful chemicals.

Hemp Textiles: Resilience and Comfort in Clothing

Hemp fibers are also suitable for textile production. Hemp textiles are known for their resilience, breathability, and comfort. Hemp fibers are naturally resistant to mold, mildew, and pests, making them an ideal material for outdoor and active wear. Additionally, hemp textiles are hypoallergenic, making them suitable for people with sensitive skin.

Industrial Hemp: A Versatile Resource for Numerous Applications

Industrial hemp is a versatile resource that can be used for various applications, including construction, textiles, composites, and food. Industrial hemp is a fast-growing crop that requires minimal water and pesticides, making it an environmentally friendly crop. Additionally, industrial hemp can be used to make biofuels, which can reduce our dependency on fossil fuels.

Hemp-Based Composites: Reinforcing Structural Integrity

Hemp fibers can also be used to reinforce composites, such as plastics and concrete, to increase their strength and durability. Hemp-based composites are lightweight, strong, and eco-friendly, making them a sustainable alternative to traditional composites. Additionally, hemp-based composites can be recycled, reducing waste and promoting sustainability.

Biodegradability and Environmental Impact of Hemp Products

Hemp products are biodegradable, which means they will naturally decompose over time without harming the environment. Additionally, hemp products do not emit harmful chemicals or toxins, making them a safe and eco-friendly option for various applications. Hemp products also require minimal water and pesticides, making them a sustainable alternative to traditional materials.

Hemp Fibers in Automotive and Aerospace Industries

Hemp fibers can also be used in the automotive and aerospace industries. Hemp fibers can be used to reinforce composites used in these industries, increasing their strength and durability. Additionally, hemp-based composites can reduce the weight of vehicles and aircraft, increasing their fuel efficiency and reducing their carbon footprint.

Challenges and Opportunities in the Hemp Fiber Industry

The hemp fiber industry still faces various challenges, including legal restrictions, lack of infrastructure, and limited research. However, the growing demand for sustainable materials and products presents significant opportunities for the hemp fiber industry. As more countries legalize hemp production, the industry is expected to grow significantly in the coming years.

Future Prospects: Advancements and Innovations in Hemp Technology

The future of the hemp fiber industry looks promising, with advancements and innovations in hemp technology expected to drive growth and development. Researchers are exploring new ways to process hemp fibers and create new materials and products from hemp. Additionally, advancements in genetic engineering may lead to the development of new hemp varieties with enhanced properties and yields.

Hemp fibers are a promising sustainable solution with various applications in construction, textiles, composites, and other industries. The exceptional strength, durability, and eco-friendliness of hemp fibers make them an attractive alternative to traditional materials and products. As the hemp fiber industry continues to grow and develop, it presents significant opportunities for sustainable development, environmental protection, and economic growth.

Home(1)

Home(1)